What is a Thin Film Resistor?

I. Introduction

In the realm of electronics, resistors play a crucial role in controlling current flow and managing voltage levels. Among the various types of resistors, thin film resistors stand out due to their precision and reliability. A thin film resistor is a passive electronic component that utilizes a thin layer of resistive material to achieve specific resistance values. These resistors are integral to modern electronic circuits, providing stability and accuracy in a wide range of applications. This article will delve into the historical background, structure, working principles, advantages, applications, and future trends of thin film resistors, offering a comprehensive understanding of their significance in contemporary technology.

II. Historical Background

The development of thin film technology can be traced back to the mid-20th century when advancements in materials science and fabrication techniques began to emerge. Initially, resistive materials were primarily bulk materials, which limited their performance and application. The evolution of thin film technology allowed for the creation of resistors with enhanced characteristics, leading to significant milestones in the field.

In the 1960s, researchers began exploring the potential of thin films, leading to the introduction of thin film resistors in commercial applications. The ability to deposit thin layers of materials with precise control opened new avenues for electronic design, paving the way for the miniaturization of components and the development of high-performance circuits.

III. Structure and Composition

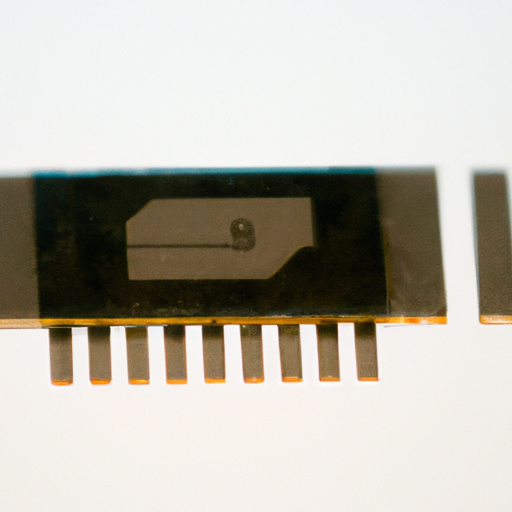

A. Basic Structure of Thin Film Resistors

Thin film resistors are composed of a substrate and a thin film layer. The substrate serves as the foundation for the resistor, providing mechanical support and electrical insulation. Common substrate materials include ceramic, glass, and silicon, each chosen for its specific properties.

The thin film layer, typically ranging from a few nanometers to several micrometers in thickness, is where the resistive action occurs. This layer is deposited onto the substrate using various techniques, allowing for precise control over the resistance value.

B. Types of Materials Used

Thin film resistors can be made from several types of materials, each offering unique characteristics:

1. **Metal Films**: Commonly used materials include gold, silver, and nickel. Metal films provide excellent conductivity and stability, making them suitable for precision applications.

2. **Metal Oxide Films**: Materials like tin oxide and indium oxide are used for their high-temperature stability and resistance to environmental factors.

3. **Other Composite Materials**: Some thin film resistors utilize composite materials that combine different elements to achieve desired electrical properties.

C. Manufacturing Processes

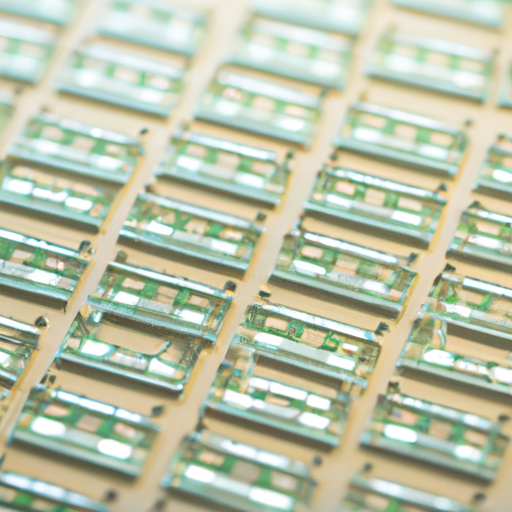

The manufacturing of thin film resistors involves several techniques, including:

1. **Sputtering**: A physical vapor deposition method where atoms are ejected from a target material and deposited onto the substrate, forming a thin film.

2. **Chemical Vapor Deposition (CVD)**: A process that involves the chemical reaction of gaseous precursors to form a solid thin film on the substrate.

3. **Other Techniques**: Additional methods such as laser ablation and inkjet printing are also employed to create thin film resistors, each offering distinct advantages.

IV. Working Principle

A. How Thin Film Resistors Function

Thin film resistors operate based on Ohm's law, where the resistance is defined as the ratio of voltage to current. The resistive layer's thickness, material properties, and temperature influence the overall resistance value.

B. Relationship Between Thickness and Resistance

The resistance of a thin film resistor is inversely proportional to its thickness. Thinner films generally exhibit higher resistance, while thicker films provide lower resistance. This relationship allows for precise tuning of resistance values during the manufacturing process.

C. Temperature Coefficient of Resistance (TCR)

The temperature coefficient of resistance (TCR) is a critical parameter for thin film resistors, indicating how resistance changes with temperature. A low TCR is desirable for applications requiring high stability across varying temperatures, making thin film resistors ideal for precision measurement devices.

V. Advantages of Thin Film Resistors

Thin film resistors offer several advantages over other types of resistors:

A. Precision and Accuracy

Thin film resistors are known for their high precision and accuracy, making them suitable for applications where exact resistance values are crucial. Their tight tolerance levels can be as low as ±0.1%, ensuring reliable performance.

B. Stability and Reliability

These resistors exhibit excellent stability over time and under varying environmental conditions. Their resistance values remain consistent, reducing the risk of circuit failure due to component drift.

C. Low Noise Characteristics

Thin film resistors generate minimal electrical noise, making them ideal for sensitive applications such as audio equipment and precision measurement devices.

D. Miniaturization and Integration into Circuits

The small size of thin film resistors allows for greater integration into compact electronic circuits, facilitating the development of smaller and more efficient devices.

VI. Applications of Thin Film Resistors

Thin film resistors find applications across various industries, including:

A. Use in Precision Measurement Devices

Instruments such as digital multimeters and oscilloscopes rely on thin film resistors for accurate measurements, ensuring reliable performance in laboratory and industrial settings.

B. Role in Telecommunications

Thin film resistors are used in telecommunications equipment to maintain signal integrity and minimize distortion, contributing to the overall performance of communication systems.

C. Applications in Automotive Electronics

Modern vehicles utilize thin film resistors in various electronic control units (ECUs) to enhance performance, safety, and fuel efficiency.

D. Integration in Consumer Electronics

From smartphones to home appliances, thin film resistors are integral to consumer electronics, providing the precision and reliability needed for everyday devices.

E. Use in Medical Devices

In the medical field, thin film resistors are employed in diagnostic equipment and monitoring devices, where accuracy and stability are paramount for patient safety.

VII. Comparison with Other Types of Resistors

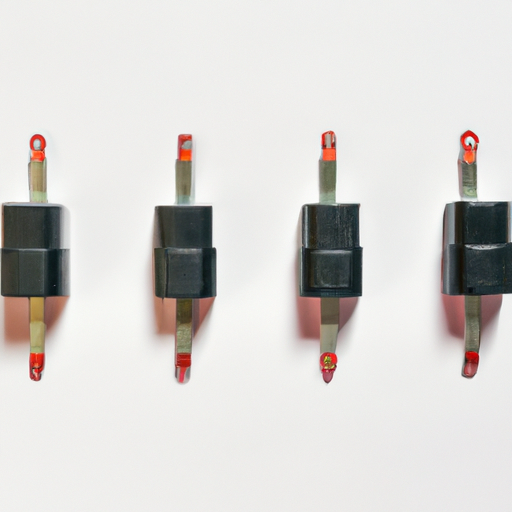

A. Thin Film vs. Thick Film Resistors

While both thin and thick film resistors are widely used, thin film resistors offer superior precision and stability, whereas thick film resistors are generally more cost-effective and suitable for high-power applications.

B. Thin Film vs. Wire-Wound Resistors

Wire-wound resistors provide high power handling capabilities but are bulkier and less precise than thin film resistors. Thin film resistors excel in applications requiring tight tolerances and low noise.

C. Advantages and Disadvantages of Each Type

Each type of resistor has its advantages and disadvantages, making them suitable for different applications. Thin film resistors are ideal for precision applications, while thick film and wire-wound resistors may be preferred for cost-sensitive or high-power scenarios.

VIII. Challenges and Limitations

A. Cost Considerations

The manufacturing processes for thin film resistors can be more expensive than those for other types of resistors, which may limit their use in cost-sensitive applications.

B. Environmental Factors Affecting Performance

Thin film resistors can be sensitive to environmental factors such as humidity and temperature, which may impact their performance in certain conditions.

C. Limitations in High-Power Applications

Due to their construction, thin film resistors are generally not suitable for high-power applications, where thicker and more robust resistors are required.

IX. Future Trends and Innovations

A. Advances in Materials Science

Ongoing research in materials science is leading to the development of new resistive materials that enhance the performance and capabilities of thin film resistors.

B. Emerging Applications in Nanotechnology

As nanotechnology advances, thin film resistors are expected to play a significant role in the development of nanoscale electronic devices, further pushing the boundaries of miniaturization.

C. Potential for Integration with Smart Technologies

The integration of thin film resistors with smart technologies, such as IoT devices and wearable electronics, presents exciting opportunities for innovation in the electronics industry.

X. Conclusion

Thin film resistors are a vital component in modern electronics, offering precision, stability, and reliability across a wide range of applications. As technology continues to evolve, the significance of thin film resistors is expected to grow, driven by advancements in materials science and the increasing demand for miniaturized and efficient electronic devices. Their role in shaping the future of technology cannot be overstated, making them an essential topic of study for anyone interested in the field of electronics.

XI. References

1. Academic papers and articles on thin film technology.

2. Industry reports detailing the applications and advancements in thin film resistors.

3. Relevant textbooks and resources on electronic components and materials science.

This comprehensive exploration of thin film resistors highlights their importance in the electronics industry and their potential for future innovations.

2025-03-04