Precautions for Training DC Resistor Products

I. Introduction

In the realm of electrical engineering, DC resistor products play a pivotal role in various applications, from industrial machinery to consumer electronics. These components are essential for controlling current flow and ensuring the stability of electrical circuits. However, the training associated with DC resistors is not without its challenges and risks. This blog post aims to highlight the importance of proper training for DC resistor products, outline the necessary precautions, and provide a comprehensive guide for trainers and trainees alike.

II. Understanding DC Resistors

A. What are DC Resistors?

DC resistors are passive electrical components that resist the flow of direct current (DC) in a circuit. Their primary function is to limit current, divide voltages, and dissipate energy in the form of heat. Understanding the different types of DC resistors—such as fixed, variable, and specialty resistors—is crucial for anyone involved in electrical training.

1. Function and Purpose

The primary purpose of a DC resistor is to control the amount of current flowing through a circuit. By doing so, they help protect sensitive components from damage and ensure that devices operate within their specified parameters.

2. Types of DC Resistors

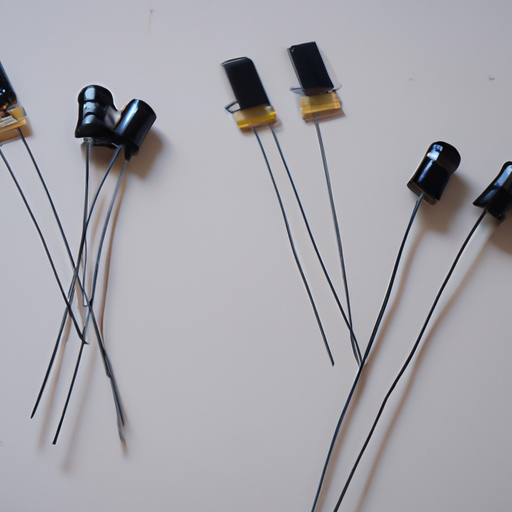

There are several types of DC resistors, including:

Fixed Resistors: These have a constant resistance value and are commonly used in circuits.

Variable Resistors: Also known as potentiometers, these allow users to adjust resistance levels.

Specialty Resistors: These include thermistors and photoresistors, which change resistance based on temperature or light exposure.

B. Applications of DC Resistors

DC resistors are utilized in a wide range of applications:

1. Industrial Uses

In industrial settings, DC resistors are used in motor control circuits, power supplies, and load testing. They help manage energy consumption and ensure the safe operation of machinery.

2. Consumer Electronics

In consumer electronics, DC resistors are found in devices such as televisions, radios, and computers, where they help regulate voltage and current.

3. Research and Development

In research and development, DC resistors are essential for prototyping and testing new electronic devices, allowing engineers to fine-tune circuit designs.

III. Importance of Safety Precautions

A. Risks Associated with DC Resistor Training

Training on DC resistors involves inherent risks that must be addressed to ensure safety.

1. Electrical Hazards

Working with electrical components poses risks such as electric shock, short circuits, and equipment failure. Proper training is essential to mitigate these hazards.

2. Equipment Damage

Improper handling of resistors and associated equipment can lead to damage, resulting in costly repairs and downtime.

3. Personal Injury

Inadequate training can lead to accidents that may cause personal injury, emphasizing the need for comprehensive safety protocols.

B. Regulatory Compliance

Compliance with industry standards and regulations is crucial for any training program. Failure to adhere to these guidelines can result in legal implications and jeopardize the safety of participants.

1. Industry Standards

Organizations such as the Institute of Electrical and Electronics Engineers (IEEE) and the National Fire Protection Association (NFPA) provide guidelines that must be followed during training.

2. Legal Implications

Non-compliance with safety regulations can lead to legal consequences, including fines and liability for injuries.

IV. Pre-Training Preparations

A. Assessing Training Needs

Before conducting training, it is essential to assess the needs of the participants.

1. Identifying Skill Levels

Understanding the skill levels of trainees allows trainers to tailor the program to meet their specific needs, ensuring that everyone benefits from the training.

2. Tailoring Training Programs

Customized training programs can address the unique challenges faced by different groups, enhancing the overall effectiveness of the training.

B. Selecting Appropriate Training Environment

The training environment plays a critical role in ensuring safety and effectiveness.

1. Safety Features

The training facility should be equipped with safety features such as emergency exits, fire extinguishers, and first aid kits.

2. Equipment Availability

Access to the necessary tools and equipment is vital for hands-on training, allowing participants to gain practical experience.

C. Gathering Necessary Materials

Preparation involves gathering all necessary materials for the training session.

1. Training Manuals

Comprehensive training manuals should be provided to participants, outlining key concepts and safety protocols.

2. Safety Gear

Personal protective equipment (PPE) such as gloves, goggles, and lab coats should be made available to all trainees.

V. Training Methodologies

A. Theoretical Training

Theoretical training lays the foundation for understanding DC resistors.

1. Understanding Electrical Principles

Participants should learn about basic electrical principles, including Ohm's Law and circuit theory, to grasp how resistors function within a circuit.

2. Learning About Resistor Specifications

Training should cover resistor specifications, including resistance values, power ratings, and tolerance levels, to ensure participants can select the appropriate components for their applications.

B. Practical Training

Hands-on experience is crucial for reinforcing theoretical knowledge.

1. Hands-On Experience

Participants should engage in practical exercises that involve assembling circuits, measuring resistance, and troubleshooting issues.

2. Simulation Tools

Utilizing simulation software can provide a safe environment for trainees to experiment with circuit designs without the risk of equipment damage.

C. Assessment and Evaluation

Evaluating participants' understanding is essential for ensuring the effectiveness of the training program.

1. Testing Knowledge

Quizzes and written tests can assess participants' theoretical knowledge and understanding of key concepts.

2. Practical Assessments

Hands-on assessments can evaluate participants' ability to apply their knowledge in real-world scenarios.

VI. Safety Protocols During Training

A. Personal Protective Equipment (PPE)

Ensuring the use of PPE is critical for participant safety.

1. Types of PPE Required

Participants should be equipped with appropriate PPE, including gloves, safety goggles, and lab coats, to protect against electrical hazards.

2. Proper Usage Guidelines

Training should include guidelines on the proper use of PPE to ensure maximum protection.

B. Emergency Procedures

Establishing clear emergency procedures is vital for addressing potential incidents.

1. First Aid Measures

Participants should be trained in basic first aid measures to respond effectively to injuries.

2. Emergency Shutdown Protocols

Clear protocols for shutting down equipment in emergencies should be established and communicated to all participants.

C. Equipment Handling

Proper handling of tools and equipment is essential for safety.

1. Safe Operation of Tools

Training should cover the safe operation of tools used in conjunction with DC resistors, including multimeters and soldering irons.

2. Maintenance and Inspection

Regular maintenance and inspection of equipment should be emphasized to prevent malfunctions and ensure safety.

VII. Post-Training Considerations

A. Continuous Learning

Training should not end with the completion of the program.

1. Importance of Ongoing Education

Encouraging participants to pursue ongoing education helps them stay updated on industry trends and safety practices.

2. Resources for Further Training

Providing resources for further training, such as online courses and workshops, can enhance participants' knowledge and skills.

B. Feedback and Improvement

Gathering feedback is essential for improving training programs.

1. Gathering Participant Feedback

Collecting feedback from participants can provide valuable insights into the effectiveness of the training and areas for improvement.

2. Updating Training Programs

Based on feedback, training programs should be regularly updated to reflect new information and best practices.

VIII. Conclusion

In conclusion, training on DC resistor products is a critical aspect of electrical engineering that requires careful consideration of safety precautions. By understanding the risks, preparing adequately, and implementing effective training methodologies, trainers can ensure a safe and productive learning environment. Continuous learning and feedback are essential for maintaining high standards in training programs. Ultimately, prioritizing safety in training not only protects participants but also fosters a culture of responsibility and professionalism in the field.

IX. References

- Institute of Electrical and Electronics Engineers (IEEE) Standards

- National Fire Protection Association (NFPA) Guidelines

- Recommended Reading: "Electrical Engineering: Principles and Applications" by Allan R. Hambley

- Contact Information for Further Inquiries: [Your Organization's Contact Information]

By adhering to these guidelines and precautions, organizations can ensure that their training programs for DC resistor products are both effective and safe, ultimately contributing to the advancement of the electrical engineering field.