Important Product Categories of Cement Resistors

I. Introduction

Cement resistors are a vital component in the world of electronics, playing a crucial role in controlling current and voltage in various circuits. These resistors are known for their durability and ability to withstand high temperatures, making them suitable for a wide range of applications. In this article, we will explore the different product categories of cement resistors, their characteristics, applications, and future trends in technology.

II. Understanding Cement Resistors

A. Composition and Structure

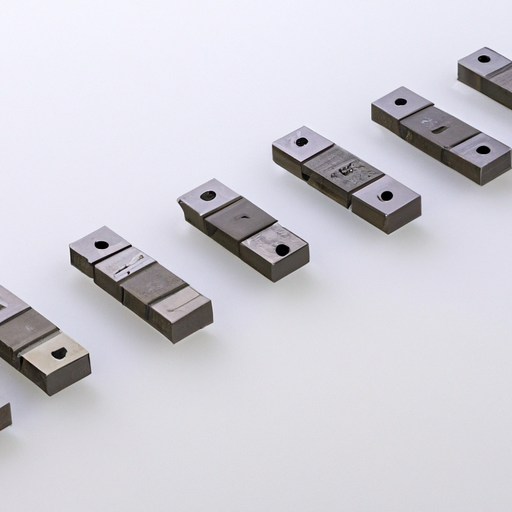

Cement resistors are typically made from a mixture of conductive materials, such as carbon or metal oxides, combined with a cement-like binder. This composition gives them their distinctive appearance and properties. The manufacturing process involves mixing these materials, shaping them into the desired form, and then curing them to achieve the necessary strength and stability.

B. Characteristics of Cement Resistors

Cement resistors are known for several key characteristics:

1. **Thermal Stability**: They can operate effectively at high temperatures, making them suitable for applications where heat dissipation is a concern.

2. **Power Rating**: Cement resistors come in various power ratings, allowing them to handle different levels of electrical power without failure.

3. **Resistance Range**: They are available in a wide range of resistance values, catering to diverse circuit requirements.

4. **Tolerance Levels**: Cement resistors typically have a tolerance level that indicates how much the actual resistance can vary from the specified value, ensuring reliability in circuit performance.

III. Key Product Categories of Cement Resistors

Cement resistors can be categorized into several key types, each with its unique features and applications.

A. Fixed Cement Resistors

**Description and Applications**: Fixed cement resistors have a predetermined resistance value that does not change. They are commonly used in applications where a stable resistance is required, such as in power supply circuits and voltage dividers.

**Advantages and Disadvantages**: The main advantage of fixed cement resistors is their simplicity and reliability. However, they lack the flexibility of variable resistors, making them less suitable for applications requiring adjustable resistance.

B. Variable Cement Resistors

**Description and Applications**: Variable cement resistors, also known as potentiometers, allow users to adjust the resistance value. They are often used in applications like volume controls in audio equipment and tuning circuits.

**Advantages and Disadvantages**: The primary advantage of variable cement resistors is their versatility, enabling users to fine-tune resistance levels. However, they may be less stable than fixed resistors and can wear out over time with frequent adjustments.

C. High-Power Cement Resistors

**Description and Applications**: High-power cement resistors are designed to handle significant amounts of electrical power, making them ideal for industrial applications, such as motor control circuits and power supply systems.

**Advantages and Disadvantages**: These resistors can dissipate heat effectively, ensuring reliable performance in demanding environments. However, they tend to be larger and more expensive than their low-power counterparts.

D. Low-Power Cement Resistors

**Description and Applications**: Low-power cement resistors are suitable for applications with lower power requirements, such as consumer electronics and small signal circuits.

**Advantages and Disadvantages**: They are typically smaller and more cost-effective than high-power resistors. However, they may not perform well in high-temperature environments or under heavy load conditions.

E. Specialty Cement Resistors

**Description and Applications**: Specialty cement resistors are designed for specific applications, such as high-voltage circuits or precision measurement devices. They may incorporate unique materials or designs to meet particular performance criteria.

**Advantages and Disadvantages**: These resistors offer tailored solutions for niche applications, ensuring optimal performance. However, they may come at a higher cost and may not be as widely available as standard resistor types.

IV. Applications of Cement Resistors

Cement resistors find applications across various industries, showcasing their versatility and reliability.

A. Industrial Applications

1. **Power Supply Systems**: Cement resistors are used in power supply circuits to regulate voltage and current, ensuring stable operation of industrial equipment.

2. **Motor Control Circuits**: They play a crucial role in controlling the speed and torque of electric motors, enhancing efficiency and performance.

B. Consumer Electronics

1. **Audio Equipment**: Cement resistors are commonly found in audio amplifiers and mixers, helping to manage signal levels and prevent distortion.

2. **Home Appliances**: They are used in various household devices, such as washing machines and microwaves, to control electrical currents and ensure safe operation.

C. Automotive Applications

1. **Engine Control Units**: Cement resistors are integral to engine management systems, helping to regulate fuel injection and ignition timing for optimal performance.

2. **Safety Systems**: They are used in automotive safety features, such as airbag deployment systems, where precise timing and control are critical.

D. Telecommunications

1. **Signal Processing**: Cement resistors are employed in signal processing circuits to manage and filter signals, ensuring clear communication.

2. **Network Equipment**: They are used in routers and switches to control current flow and protect sensitive components from voltage spikes.

V. Factors to Consider When Choosing Cement Resistors

When selecting cement resistors for a specific application, several factors should be considered:

A. Resistance Value

The resistance value must match the requirements of the circuit to ensure proper functionality.

B. Power Rating

Choosing a resistor with an appropriate power rating is crucial to prevent overheating and potential failure.

C. Tolerance and Temperature Coefficient

Understanding the tolerance levels and temperature coefficients helps ensure that the resistor will perform reliably under varying conditions.

D. Environmental Considerations

Consider the operating environment, including temperature, humidity, and exposure to chemicals, to select a resistor that can withstand these conditions.

E. Cost and Availability

Budget constraints and the availability of specific resistor types can influence the selection process.

VI. Future Trends in Cement Resistor Technology

As technology continues to evolve, several trends are shaping the future of cement resistors:

A. Innovations in Materials

Research is ongoing to develop new materials that enhance the performance and durability of cement resistors, potentially leading to improved thermal stability and power handling.

B. Miniaturization and Integration

The trend towards smaller electronic devices is driving the need for miniaturized resistors that can be integrated into compact circuit designs without compromising performance.

C. Sustainability and Eco-Friendly Options

With increasing awareness of environmental issues, manufacturers are exploring eco-friendly materials and production processes to create sustainable cement resistors.

VII. Conclusion

Cement resistors are an essential component in a wide range of electronic applications, offering durability, thermal stability, and versatility. Understanding the different product categories—fixed, variable, high-power, low-power, and specialty resistors—can help engineers and designers make informed choices for their specific needs. As technology advances, the future of cement resistors looks promising, with innovations in materials, miniaturization, and sustainability paving the way for enhanced performance and reliability.

VIII. References

1. Academic Journals on Electronics and Materials Science

2. Industry Reports on Resistor Technology

3. Manufacturer Specifications and Product Catalogs

In summary, cement resistors play a critical role in modern electronics, and their various categories cater to a wide array of applications. By considering the factors outlined in this article, one can make informed decisions when selecting the right cement resistor for any project.