What is a Product of Wire Winding Resistor?

I. Introduction

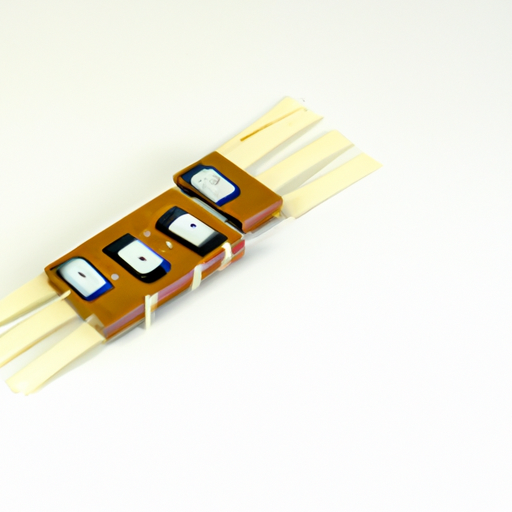

A. Definition of Wire Winding Resistor

A wire winding resistor is a type of electrical resistor that is constructed by winding a resistive wire around a core or a frame. This design allows for a high degree of precision and power handling capability, making wire winding resistors a popular choice in various applications, particularly in power electronics and audio equipment.

B. Importance of Wire Winding Resistors in Electrical Engineering

In the realm of electrical engineering, resistors play a crucial role in controlling current flow, managing voltage levels, and ensuring the stability of circuits. Wire winding resistors, in particular, are valued for their ability to handle high power levels and provide accurate resistance values, which are essential for the performance of many electronic devices.

C. Purpose of the Article

This article aims to provide a comprehensive overview of wire winding resistors, exploring their construction, applications, advantages, disadvantages, manufacturing processes, and future trends. By the end of this article, readers will have a deeper understanding of wire winding resistors and their significance in modern technology.

II. Understanding Wire Winding Resistors

A. Basic Principles of Resistors

1. Ohm's Law

At the core of understanding resistors is Ohm's Law, which states that the current (I) flowing through a conductor between two points is directly proportional to the voltage (V) across the two points and inversely proportional to the resistance (R) of the conductor. This relationship is expressed mathematically as V = I × R.

2. Resistance and Conductivity

Resistance is a measure of the opposition to current flow in an electrical circuit. It is influenced by factors such as the material's resistivity, length, and cross-sectional area. Conductivity, on the other hand, is the ability of a material to conduct electric current, which is the inverse of resistance.

B. Types of Resistors

1. Fixed Resistors

Fixed resistors have a constant resistance value and are commonly used in circuits where a specific resistance is required.

2. Variable Resistors

Variable resistors, such as potentiometers, allow users to adjust the resistance value, making them suitable for applications like volume controls in audio equipment.

3. Specialty Resistors

Specialty resistors are designed for specific applications, such as thermistors for temperature sensing or photoresistors for light detection.

C. Overview of Wire Winding Resistors

1. Construction and Materials

Wire winding resistors are typically made from high-resistivity materials such as nickel-chromium or copper-nickel alloys. The wire is wound around a core, which can be made from ceramic, fiberglass, or other insulating materials, to provide structural support and thermal management.

2. How Wire Winding Resistors Work

The resistance of a wire winding resistor is determined by the length and cross-sectional area of the wire, as well as the resistivity of the material. When an electric current passes through the resistor, it generates heat due to the resistance, which can be managed through proper design and materials.

III. Applications of Wire Winding Resistors

A. Power Electronics

1. Use in Power Supplies

Wire winding resistors are commonly used in power supplies to regulate voltage and current levels, ensuring stable operation of electronic devices.

2. Role in Motor Control

In motor control applications, wire winding resistors help manage the current flowing to the motor, allowing for precise control of speed and torque.

B. Audio Equipment

1. Impedance Matching

In audio systems, wire winding resistors are used for impedance matching, ensuring that the output of one component is compatible with the input of another, which is crucial for optimal sound quality.

2. Signal Processing

Wire winding resistors play a role in signal processing circuits, where they help shape and filter audio signals.

C. Industrial Applications

1. Load Testing

Wire winding resistors are often employed in load testing applications to simulate the load on electrical systems, allowing engineers to assess performance and reliability.

2. Heating Elements

Due to their ability to handle high power levels, wire winding resistors can also be used as heating elements in various industrial processes.

D. Research and Development

1. Prototyping

In research and development, wire winding resistors are used in prototyping new electronic devices, providing accurate resistance values for testing and experimentation.

2. Experimental Setups

Wire winding resistors are essential in experimental setups where precise control of electrical parameters is required.

IV. Advantages of Wire Winding Resistors

A. High Power Handling Capability

One of the primary advantages of wire winding resistors is their ability to handle high power levels without overheating, making them suitable for demanding applications.

B. Precision and Stability

Wire winding resistors offer high precision and stability in resistance values, which is critical for applications requiring accurate measurements and control.

C. Customizability

These resistors can be customized in terms of resistance value, size, and power rating, allowing engineers to tailor them to specific applications.

D. Thermal Management

The design of wire winding resistors allows for effective thermal management, reducing the risk of overheating and ensuring reliable performance.

V. Disadvantages of Wire Winding Resistors

A. Size and Weight Considerations

Wire winding resistors tend to be larger and heavier than other types of resistors, which can be a disadvantage in applications where space and weight are critical factors.

B. Cost Factors

The manufacturing process for wire winding resistors can be more complex and costly compared to other resistor types, which may limit their use in budget-sensitive projects.

C. Limited Availability of Certain Types

Some specialized wire winding resistors may have limited availability, making it challenging for engineers to source the exact components they need.

VI. Manufacturing Process of Wire Winding Resistors

A. Material Selection

The first step in manufacturing wire winding resistors is selecting the appropriate materials, including the resistive wire and insulating core.

B. Winding Techniques

The wire is then wound around the core using precise techniques to ensure uniformity and consistency in resistance values.

C. Insulation and Coating

After winding, the resistor is insulated and coated to protect it from environmental factors and to enhance thermal management.

D. Quality Control Measures

Quality control measures are implemented throughout the manufacturing process to ensure that the resistors meet specified performance standards.

VII. Future Trends in Wire Winding Resistors

A. Innovations in Materials

Research is ongoing into new materials that can enhance the performance and efficiency of wire winding resistors, potentially leading to lighter and more compact designs.

B. Advances in Manufacturing Techniques

Advancements in manufacturing techniques, such as automation and precision winding, are expected to improve the consistency and reduce the cost of wire winding resistors.

C. Integration with Smart Technologies

As the demand for smart technologies grows, wire winding resistors may be integrated into smart devices, enabling enhanced functionality and performance.

VIII. Conclusion

A. Summary of Key Points

Wire winding resistors are essential components in electrical engineering, offering high power handling capability, precision, and customizability. They find applications in power electronics, audio equipment, industrial processes, and research and development.

B. The Role of Wire Winding Resistors in Modern Technology

As technology continues to evolve, wire winding resistors will play a critical role in ensuring the reliability and performance of electronic devices across various industries.

C. Final Thoughts on Their Importance in Electrical Engineering

Understanding wire winding resistors and their applications is vital for engineers and technicians working in the field. Their unique properties make them indispensable in many high-performance applications, and ongoing innovations will likely enhance their relevance in the future.

IX. References

A. Academic Journals

- IEEE Transactions on Power Electronics

- Journal of Electrical Engineering & Technology

B. Industry Publications

- Electronic Design Magazine

- Power Electronics Technology

C. Technical Manuals and Guides

- Resistor Technology Handbook

- Electrical Engineering Fundamentals

This blog post provides a detailed exploration of wire winding resistors, highlighting their significance in electrical engineering and their diverse applications in modern technology.