What are the Popular Color Ring Resistor Models?

Introduction

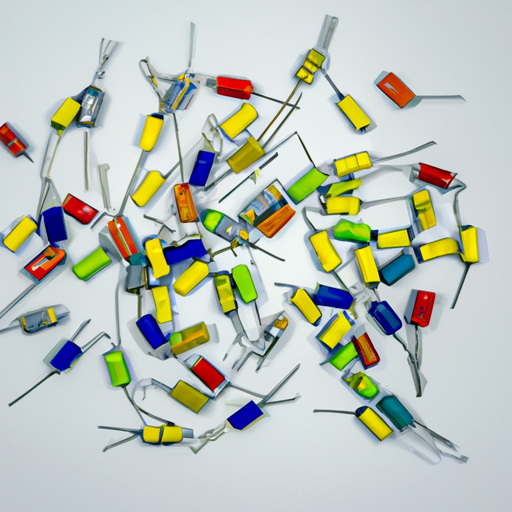

Resistors are fundamental components in electronic circuits, playing a crucial role in controlling current flow and voltage levels. They are essential for protecting sensitive components, dividing voltages, and setting bias points in various applications. One of the most recognizable features of resistors is their color coding system, which provides a quick and efficient way to identify their resistance values and tolerances. This article aims to explore popular color ring resistor models, their characteristics, and their applications in modern electronics.

1. Understanding Resistor Color Codes

1.1 The Basics of Resistor Color Coding

The color code system for resistors consists of a series of colored bands printed on the resistor's body. Each color corresponds to a specific number, allowing users to determine the resistor's value at a glance. Typically, resistors have four or five color bands, where the first two or three bands represent significant digits, the next band indicates the multiplier, and the final band denotes tolerance.

For example, a resistor with bands of red, red, and brown would have a resistance value of 22 ohms (2 and 2) multiplied by 10 (the brown band), resulting in 220 ohms. The tolerance band, often gold or silver, indicates how much the actual resistance can vary from the stated value.

Understanding the significance of each color is vital for anyone working with electronic components. The standard color code chart includes the following colors and their corresponding values:

- Black: 0

- Brown: 1

- Red: 2

- Orange: 3

- Yellow: 4

- Green: 5

- Blue: 6

- Violet: 7

- Gray: 8

- White: 9

1.2 The Standard Color Code Chart

The standard color code chart is an essential reference for anyone dealing with resistors. It not only helps in identifying resistance values but also provides insights into the tolerance levels of resistors. Tolerance is typically represented by the following colors:

- Brown: ±1%

- Red: ±2%

- Green: ±0.5%

- Blue: ±0.25%

- Violet: ±0.1%

- Gold: ±5%

- Silver: ±10%

Understanding these codes is crucial for ensuring that the right resistor is used in a circuit, as incorrect values can lead to circuit failure or suboptimal performance.

2. Popular Resistor Models

2.1 Carbon Film Resistors

Carbon film resistors are one of the most common types of resistors used in electronic circuits. They are made by depositing a thin layer of carbon on a ceramic substrate, which is then cut into a spiral to create resistance. These resistors are known for their stability and reliability.

**Advantages:**

- Cost-effective and widely available.

- Good temperature stability.

- Suitable for general-purpose applications.

**Disadvantages:**

- Limited precision compared to metal film resistors.

- Higher noise levels.

**Common Applications:**

Carbon film resistors are often used in consumer electronics, audio equipment, and general-purpose circuits. Typical resistance values range from a few ohms to several megaohms.

2.2 Metal Film Resistors

Metal film resistors are constructed using a thin film of metal, which provides better precision and stability than carbon film resistors. They are known for their low noise and high accuracy.

**Comparison with Carbon Film Resistors:**

Metal film resistors generally offer lower tolerance levels (±1% or better) and are less affected by temperature changes, making them ideal for precision applications.

**Applications:**

These resistors are commonly used in high-precision circuits, such as instrumentation, audio equipment, and high-frequency applications.

2.3 Wirewound Resistors

Wirewound resistors are made by winding a metal wire around a ceramic or fiberglass core. They are designed to handle high power and are often used in applications where heat dissipation is critical.

**Benefits:**

- High power ratings and excellent heat dissipation.

- Suitable for high-frequency applications.

**Typical Resistance Values:**

Wirewound resistors can range from a few ohms to several kilo-ohms, depending on the application.

**Applications:**

They are commonly used in power supplies, amplifiers, and industrial equipment.

2.4 Thick and Thin Film Resistors

Thick and thin film resistors are manufactured using different deposition techniques. Thick film resistors are made by printing a paste of resistive material onto a substrate, while thin film resistors are created by depositing a thin layer of resistive material.

**Differences:**

- Thick film resistors are generally less expensive and have higher tolerances, while thin film resistors offer better precision and stability.

**Applications:**

Both types are widely used in modern electronic devices, including smartphones, computers, and automotive applications.

3. Specialty Resistor Models

3.1 Variable Resistors (Potentiometers)

Variable resistors, commonly known as potentiometers, allow users to adjust resistance values manually. They consist of a resistive element and a movable contact that slides along the element.

**Applications:**

Potentiometers are widely used in audio equipment for volume control, in adjustable circuits, and in various consumer electronics.

**Popular Models:**

Common potentiometer models include linear and logarithmic types, with specifications varying based on resistance range and power rating.

3.2 SMD Resistors

Surface Mount Device (SMD) resistors are designed for surface mounting on printed circuit boards (PCBs). They are compact and offer several advantages over traditional through-hole resistors.

**Advantages:**

- Space-saving design.

- Improved performance at high frequencies.

- Automated assembly processes.

**Common SMD Resistor Models:**

Popular SMD resistor sizes include 0402, 0603, and 0805, with resistance values ranging from a few ohms to several megaohms.

3.3 High-Precision Resistors

High-precision resistors are designed for applications requiring exceptional accuracy and stability. They are often used in measurement and calibration equipment.

**Applications:**

These resistors are critical in scientific research, medical devices, and high-end audio equipment.

**Popular Models:**

Common high-precision resistor models include those with tolerances of ±0.1% or better, often made from metal film materials.

4. Choosing the Right Resistor Model

4.1 Factors to Consider

When selecting a resistor, several factors must be considered:

Resistance Value: Ensure the resistor meets the circuit's requirements.

Tolerance: Choose a resistor with an appropriate tolerance for the application.

Power Rating: Ensure the resistor can handle the power without overheating.

Environmental Considerations: Consider temperature, humidity, and other environmental factors that may affect performance.

4.2 Common Mistakes to Avoid

Misreading Color Codes: Always double-check the color bands to avoid errors.

Choosing the Wrong Type: Ensure the resistor type matches the application requirements.

Ignoring Tolerance and Power Ratings: These factors are crucial for reliable circuit performance.

5. Conclusion

Understanding resistor models and their color codes is essential for anyone involved in electronics. From carbon film to high-precision resistors, each type has its unique characteristics and applications. By familiarizing yourself with these components, you can make informed decisions when designing and building electronic circuits. We encourage you to explore further and experiment with different resistor types to enhance your knowledge and skills in electronic design and innovation.

References

- "The Art of Electronics" by Paul Horowitz and Winfield Hill

- "Electronic Components: A Complete Reference for Project Builders" by Delton T. Horn

- Online resources such as Digi-Key, Mouser Electronics, and educational websites on electronics.